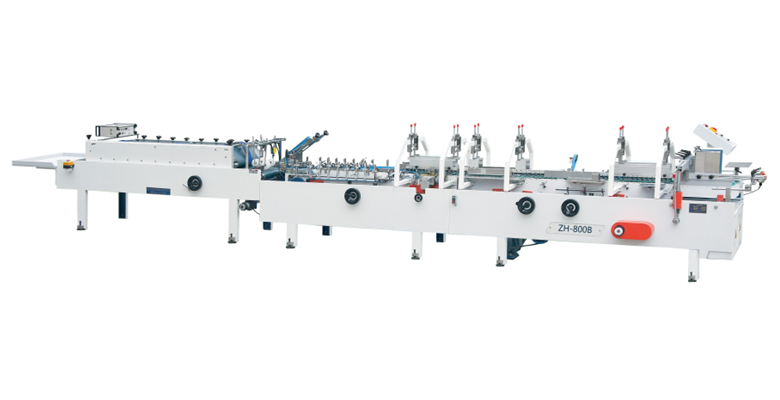

Operation for Folder Gluer

1. Add lubricating oil to each filling point

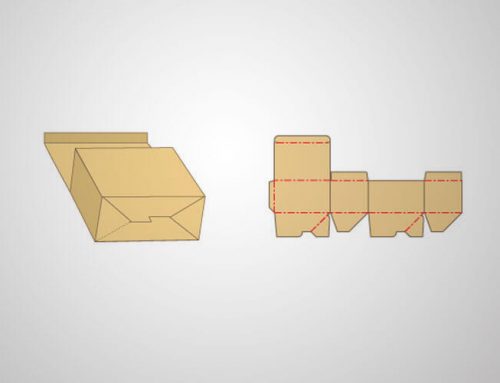

2. Read the production process notice to confirm the product to be pasted

3. Adjust both sides of the cardboard according to the size and width of the carton to make it moderate.

4. Adjust the paper blocking knife at the front of the carton and the paper pushing bar at the rear to make the carton lean forward and keep parallel.

5. Adjust the gap between the paper blocking knife and the belt so that the paper can just pass through one sheet.

6. Jog to observe whether the box is skewed and scratched, and make appropriate fine adjustment

7. Jog the machine to stop the carton at the front end of the glue groove, use the handle to adjust the position of the rubber wheel, and adjust the gluing and paper pressing bearing to make the gluing uniform.

8. If the paper box needs to be polished, the paper bearing can be polished according to the paper thickness.

9. According to the personnel, the size of the paper to determine the speed of work.

10. After finishing the work, remove the dust left by the machine after grinding, and clean the glue adhered to the conveyor belt.

11. Turn off the power.

12. Fill in the work record and quality flow card, and check whether the packaged products are well marked.

Maintenance for Folder Gluer Machine

1. The machinery should be kept clean and cleaned regularly every day.

2. Scrub the mechanical belt with clean water every day to keep it clean and prevent slipping, especially to prevent grinding dust sticking on the belt. At the end of the work, clean the dust adsorbed on the belt by grinding the paper with clean water.

3. Speed regulation is strictly prohibited when the governor stops, otherwise the belt will be seriously worn.

4. The support, shaft and screw of inner row plate should be cleaned frequently, and the lubricating oil should be added to ensure that the adjustment is easy and smooth

5. It’s better to drive slowly before starting the machine to check whether the machine is abnormal.

6. Add lubricating oil to the transmission part of the machine regularly and regularly

7. Regularly and regularly check the balance and flexibility between the supporting shafts of the conveyor belt and adjust them in time

8. If equipped with glue spraying system. The spray gun should be kept clean every day. When not in use, it should be cleaned and properly kept

9. Always pay attention to the electrical components on the equipment and whether the frequency converter works normally.

10. At the end of the work, the glue box must be cleaned to avoid a series of consequences caused by residual glue solidification.

Leave A Comment